Chain plate conveyor is a type of conveying mechanical equipment that uses a 360 ° cyclic bent plate chain and corresponding sprocket to cooperate with each other as traction power, with metal plates...

【Product Overview】:

The plate chain feeder is a conveying device used in waste treatment production lines for uniform and continuous feeding. It is suitable for stable material distribution to upstream equipment such as crushers and screening machines, effectively controlling the feeding speed and flow rate, and improving the operating efficiency and stability of downstream equipment.

【Production Capacity】:

20–400 t/h (adjustable according to chain width, operating speed, and material characteristics)

【Applicable Objects】:

Quantitative feeding scenarios for lumpy, loose, or water-containing viscous materials such as municipal solid waste, construction waste, industrial solid waste, slag, and crushed mixtures.

【Product Aliases】:

Chain plate feeder, plate feeder, heavy-duty feeder, waste chain plate material distributor, uniform speed feeding conveyor

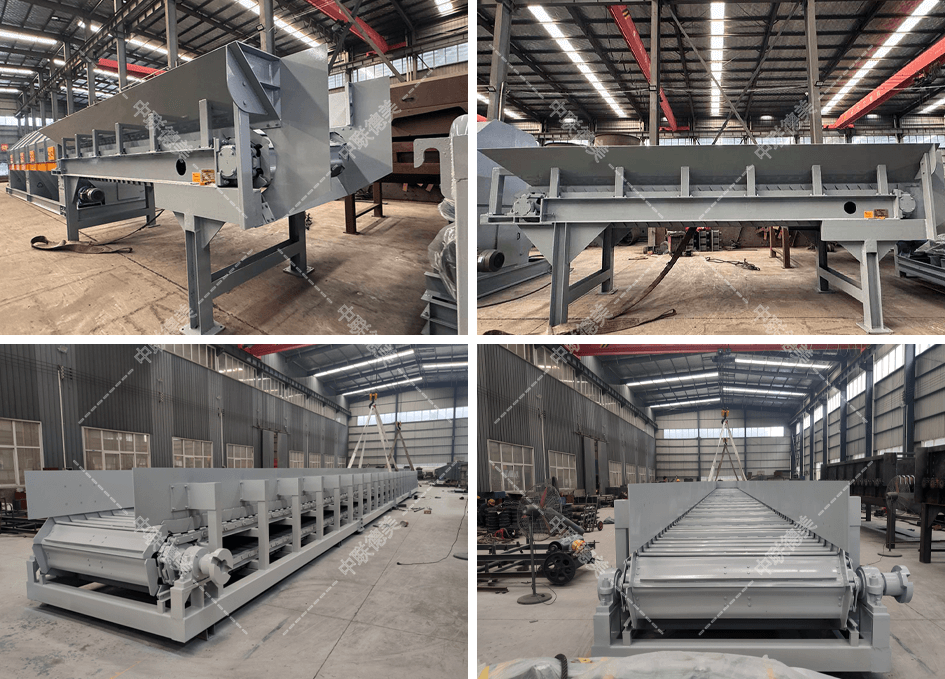

【Product Images】:

【Product Introduction】:

This equipment adopts high-strength chain plates and a heavy-duty transmission structure, possessing excellent wear resistance and impact resistance, suitable for complex waste material conditions. The equipment's operating speed is adjustable, and the feeding rate is controllable, effectively preventing material accumulation or interruption, ensuring continuous and stable operation of downstream equipment. It can be used in conjunction with equipment such as bar screens, bag breakers, and crushers.

【Working Principle】:

A motor-driven reducer drives the main drive sprocket, which in turn pulls the chain plate to run smoothly along the guide rail. Material falls from the hopper or upstream equipment onto the chain plate surface and is conveyed forward at a uniform speed. The feed rate is controlled by adjusting the chain plate speed or the gate opening, achieving quantitative and uniform material distribution.

【Product Advantages】:

1. Good Feeding Stability: Adjustable operating speed helps control material flow and reduce impact on downstream equipment;

2. Adaptable to Various Materials: Can convey lumpy, sticky, wet, or mixed waste materials without easily clogging or slipping;

3. High Structural Strength: The chain plate and frame are made of thickened wear-resistant materials, suitable for heavy-duty continuous operation;

4. Relatively Convenient Maintenance: Modular design of key components allows for individual replacement after localized wear;

5. Flexible Control Methods: Supports manual speed adjustment or integration with PLC automatic control systems, adaptable to intelligent production lines;

6. Strong Layout Adaptability: Can be installed horizontally or at a slight angle, facilitating connection with different equipment;

7. Low Operating Noise: Optimized transmission system design keeps vibration and noise within a reasonable range.

【Shipping Photos】:

| Model | Power(kw) | Chain plate width (mm) | Chain plate length (mm) | Chain plate thickness (mm) |

|---|---|---|---|---|

| BL-1040 | 5.5 | 1000 | 4000 | 6-10 |

| BL-1240 | 7.5-11 | 1200 | 4000 | 6-10 |

| BL-1440 | 7.5-11 | 1400 | 4000 | 6-10 |

Leave your contacts and our engineers will help you to find the solution you are looking for.

Hi! Welcome back.

How are you doing?

Let s talk! We’ll provide the perfect solution for you!

Since its establishment, Zhonglian Demei Machinery has been focusing on comprehensive solutions for various garbage sorting and processing. It has excellent quality in design, research, production, and manufacturing.

Guhuang Road, Wen County, Jiaozuo City, Henan Province, China