Chain plate conveyor is a conveying equipment used for continuous transportation of large volume, heavy or irregular materials in garbage treatment production lines. It is suitable for front-end feeding, intermediate transportation and back-end discharge,

【Product Overview】:

Chain conveyors are conveying equipment used in waste treatment production lines for the continuous transport of large-volume, heavy, or irregular materials. They are suitable for front-end feeding, intermediate transport, and rear-end discharge, featuring high load-bearing capacity, stable operation, and adaptability to complex working conditions.

【Production Capacity】:

10–500 t/h (adjustable according to chain width, operating speed, and material density)

【Applicable Materials】:

Municipal waste, construction and renovation waste, industrial solid waste, large-item waste crushing, slag, and mixed scrap metal materials, as well as other coarse, sharp, or moist materials.

【Alternative Names】:

Chain conveyor, heavy-duty chain conveyor, waste chain feeder, plate conveyor, scraper chain conveyor

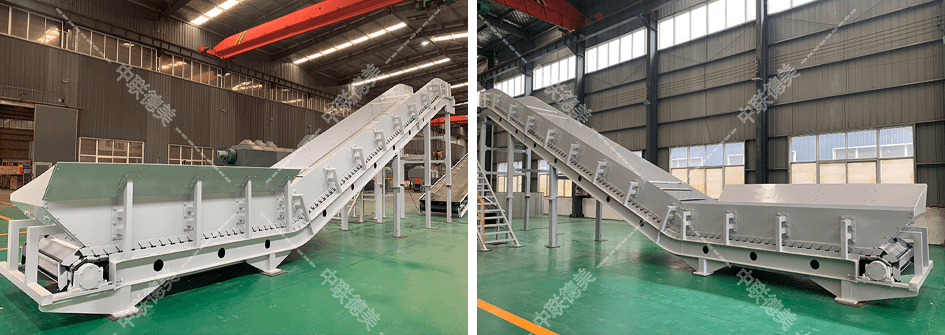

【Product Images】:

【Product Introduction】:

This equipment uses high-strength alloy steel chain plates and a heavy-duty transmission structure, capable of withstanding impact loads and abrasive materials. The chain plate surface can be optionally equipped with anti-slip, anti-corrosion, or wear-resistant treatments, adapting to complex waste treatment environments such as dampness, corrosion, and sharp objects. The equipment's tilt angle is adjustable, supporting both horizontal and inclined arrangements, facilitating integration with bag-breaking machines, screening machines, crushers, and other equipment.

【Working Principle】:

The drive unit rotates the main sprocket, pulling the chain and chain plates along the track in a cyclical motion. Material falls onto the chain plates from the feed end and is smoothly conveyed forward to the discharge end. The equipment's operating speed is adjustable, allowing control of the material conveying rhythm according to process requirements.

【Product Advantages】:

1. High Load Capacity: Suitable for conveying heavy, large, or high-density materials;

2. Good Adaptability: Can handle sharp, wet, and sticky waste, less prone to clogging or slippage;

3. Sturdy and Durable Structure: The frame and chain plates are made of thickened steel, impact-resistant and wear-resistant;

4. Smooth and Reliable Operation: Low-speed, high-torque transmission reduces material rolling or spillage;

5. Relatively Convenient Maintenance: Adjustable chain tensioning device, modular chain plates, easy partial replacement;

6. Flexible Layout: Supports horizontal and inclined installation methods, adaptable to different production line layouts;

7. Easy Linkage Control: Can be connected to a PLC system, coordinating with upstream and downstream equipment to improve the automation level of the production line.

【Shipping Photos】:

| Model | Power(kw) | Chain plate width (mm) | Chain plate length (mm) | Chain plate thickness (mm) |

|---|---|---|---|---|

| BL-10130 | 7.5 | 1000 | 13000 | 6-10 |

| BL-12130 | 11 | 1200 | 13000 | 6-10 |

| BL-14130 | 11 | 1400 | 13000 | 6-10 |

Leave your contacts and our engineers will help you to find the solution you are looking for.

Hi! Welcome back.

How are you doing?

Let s talk! We’ll provide the perfect solution for you!

Since its establishment, Zhonglian Demei Machinery has been focusing on comprehensive solutions for various garbage sorting and processing. It has excellent quality in design, research, production, and manufacturing.

Guhuang Road, Wen County, Jiaozuo City, Henan Province, China